Contact Us

5 Hazelgrove Road,

Haywards Heath,

England, RH16 3PH

Get Connected

- [email protected]

- 01293 222 622

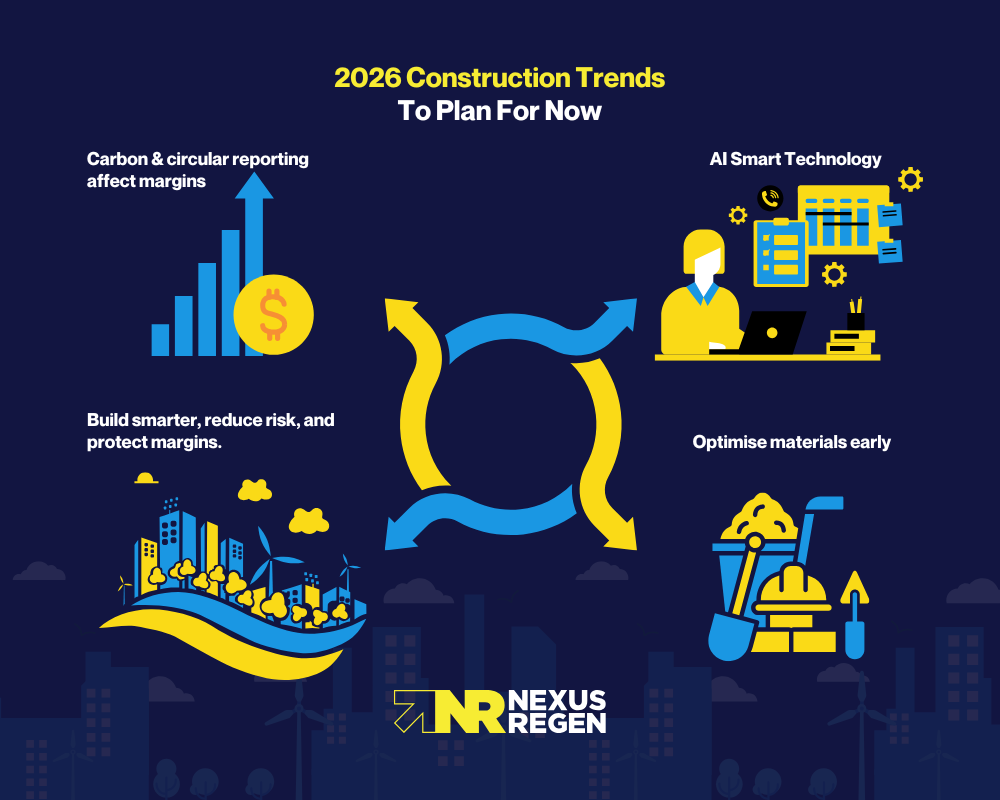

The construction sector enters 2026 with pressure building on every front. Landfill tax rises in April, carbon disclosure rules tighten, and clients are asking harder questions about where materials come from and where they end up.

We’ve talked about sustainability for years, but now the numbers have teeth. Every part of delivery now touches on materials, data, and transparency. Waste isn’t just an environmental concern anymore, it’s now a measurable cost.

The organisations that will stay ahead this year are those that treat data, materials, and collaboration as part of the same operational system. Here are the 2026 construction trends that will shape how we build, bid, and manage risk through 2026.

Landfill tax will rise again in April 2026, reinforcing what many have already recognised: disposal is no longer just an environmental issue, it’s an economic one.

Across the UK, projects are rethinking how they manage material flow, with early-stage modelling now seen as a core part of cost planning.

We’re seeing stronger integration between geotechnical data, cut-and-fill design, and live material tracking systems. This shift means surplus soil and aggregates are viewed as valuable inputs, not waste streams.

Companies that can measure reuse, diversion from landfill, and avoided haulage are starting to use those metrics directly in their tender submissions. That evidence now influences both pricing and client confidence.

Practical playbook:

Treat SI data, borehole logs and cut‑fill as a live “materials balance sheet” at pre‑con.

Prioritise secondary and recycled products where compliant.

Quantify avoided landfill tax and haulage reductions in bid narratives and post‑project reports.

This aligns with a broader industry push to engineer out waste and make reuse the default, not the exception.

Artificial intelligence tools are being embedded across pre-construction and project delivery. These systems read reports, classify materials, flag compliance actions, and forecast material surpluses or deficits before they affect the schedule.

At pre-construction, AI tools are cross-referencing ground data, predicting surplus volumes, and generating compliant documentation. During delivery, they’re matching those surpluses with nearby import needs to reduce haulage.

This saves time on coordination and supports evidence-based reporting. What used to take days of manual reconciliation between spreadsheets now happens automatically. It means decisions are made earlier, with better information.

AI isn’t replacing project managers – it’s removing the hours they used to spend chasing data. It’s time to get comfortable with maximising what AI has to offer, not burying your head in the sand.

Projects that can show tonnes diverted from landfill, CO₂e saved, and documented material provenance are being rated higher for both compliance and innovation.

Reporting platforms can now translate material movements into tonnes of CO₂e saved, allowing contractors to quantify the environmental and financial impact of their choices.

Reporting expectations in 2026:

Re-use and recycled content tracked by work package.

Verified audit trails for DoW CoP and testing.

Standardised data for carbon reporting.

Circular performance has become part of how financial performance is judged.

Rising costs, limited availability of virgin aggregate, and improved testing standards are accelerating the use of secondary materials. Confidence is growing thanks to better documentation and quality control frameworks, which make it easier to demonstrate compliance.

More tenders explicitly allow or even require recycled content, while suppliers that can surface testing data and traceability digitally are gaining stronger market share.

The combination of cost pressure and reliable certification means secondary materials are finally being treated as mainstream.

Contractors that build secondary material use into their early design and procurement decisions are positioning themselves to avoid both delays and cost spikes later in the programme.

Compliance planning is being integrated into early design. Frameworks such as CL:AIRE DoW CoP and the DEFRA soil code are now referenced during pre-construction rather than left for post-approval.

This shift helps teams manage risk and reduces costly disposal or re-work later in the programme. Testing, documentation, and digital traceability are becoming standard elements of early planning.

Front-loaded compliance saves time and cost further down the line.

The year ahead will reward firms that operate with clarity, efficiency, and purpose. As landfill taxes increase and digital capabilities accelerate, the smartest move for construction leaders is to place material optimisation and data-driven strategy at the heart of their delivery models. Circular, connected, and AI-empowered approaches will no longer be niche; they will be the standard.

Looking to align your projects with 2026 trends? Nexus ReGen helps clients stay ahead of the curve. Let’s build smarter, together.

5 Hazelgrove Road,

Haywards Heath,

England, RH16 3PH